Contact Information

info@leanconstructionblog.com

Articles By This Author

Last Planner and Takt Software Directory

This directory contains all of the Last Planner and Takt Software on the market. We encourage you to do your own research, set up a call with the vendors, and choose the software that fits your needs. This directory is meant to make it easy to find, compare, and make the decision on which software you can use.

Building an internal lean infrastructure to scale up lean deployment in a company with over 10,000 employees

WasteWalk Observations have led to the identification of over $300MM worth of estimated and $52MM of actual net cost savings/added value on over 300 projects and yards. 2024 saw the highest employee engagement in WasteWalks since introducing them as a Building Smarter best practice in 2022.

A Beginner’s Guide to Learning about Lean Construction

In this blog post, I will share my guide for beginners. I will focus exclusively on what a beginners needs to focus on during the first 6 months of their lean journey.

What is the Lean Construction Pyramid? And how can you use it to simplify your understanding and Lean implementation?

The field of lean design and construction has been around for more than 30 years. Over time our goal is to make lean design and construction simpler, not more complex.

You can't be successful with lean design and construction without being part of a community

If you have been practicing lean design and construction for several years, you will realize the importance of being part of a community. Why is community involvement crucial?

Why Target Value Design And Integrated Project Delivery? A Tale Of Two Cities

Two sister cities, Rosencrantz and Guildenstern, have both decided to each build a new library for their citizens. Both cities have roughly the same budget (100 million coins) and a schedule of 3 years (for both design and construction).

How to use the Lean Construction Blog to support your study action team (SAT) and internal training

As you are embarking on your Lean Construction, one of the most important and challenging things to do is training your team. In large organizations, there may be only one or two lean experts in a company with thousands of employees.

8 Misconceptions about Lean Construction

What are some misconceptions about Lean Construction that you would like to clear up? This is a question that I get a lot and knowing some of these misconceptions can save you years on your Lean Journey.

An Introduction to Target Value Delivery

Target Value Delivery (TVD) is “a management practice that drives the design [and construction] to deliver customer values within project constraints” (Ballard, 2009). It is an application of Taiichi Ohno’s practice of self-imposing necessity as a means for continuous improvement (Ballard, 2009).

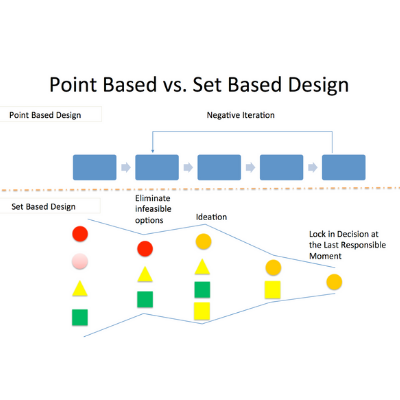

An Introduction to Set Based Design

Set-based Design (SBD) is a design methodology that has many applications in the architecture, engineering, and construction (AEC) industry. It was discovered when researcher studied the engineering and design process at Toyota [1]. Known as the “second Toyota paradox”.

Integrating Design and Construction using the VDC Framework

Many projects struggle with innovation because they approach it through a siloed perspective. Some projects are great at contech, BIM, or lean. Very few projects have a means of integrating all these great ideas together.

An A3 Template for Lean Research

In Lean Construction, we recognize that there are inherent wastes in every production system. Our objective is often to identify and reduce the wastes. Just as construction and design have been conceptualized as production systems, it can be argued that research is also a production system.

Highlighting 12 Papers from the IGLC 2019 Conference

The International Group For Lean Construction (IGLC) is an international conference started in 1993. The IGLC brings together an international community of researchers and industry practitioners each summer to advance the research and practical applications of Lean Design and Construction.

Applying the Last Planner in a Small HVAC Company

According to the US Bureau of Labor Statistics, there are 6.5 million people working in the US construction industry in 2016. The average construction worker is statistically more likely to work in a small or medium business than a large multi-billion company.

Applying Kanban at a Small HVAC Company

This blog post is a continuation of our series on the application of Lean Construction methods in a small HVAC Company. The goal of this post is to show how a small company applied Kanban to manage their work processes.

7 Ways to Make Shared Risk and Reward Sustainable in the Construction Industry

Around the world, shared risk and reward contracts are becoming more prevalent. In the United States several forms of agreements for construction projects including: Sutter Health’s Integrated Form of Agreement (IFOA), the ConsensusDocs 300, and American Institute of Architects (AIA) contracts.

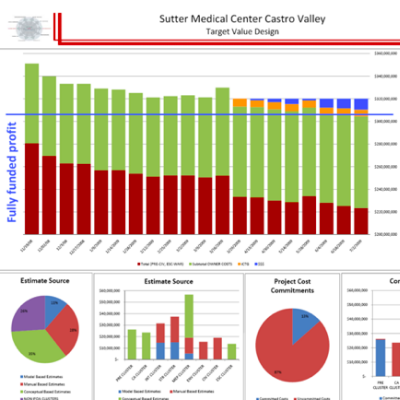

How Target Value Design Works. A Theoretical Model

Research on Target Value Design (TVD) has found that TVD projects are delivered 15% to 20% below market price1. Additionally, TVD projects are more likely to achieve predictable cost performance outcomes while carry less contingency than projects that do not use TVD2.

Target Value Design as a Method for Controlling Project Cost Overrun

Project cost overrun is a common problem around the world. A study of 258 projects in 20 nations revealed that cost escalation occurred in 9 out of 10 projects. The study found that on average the final cost was 28% higher than the forecasted cost. Cost overrun is a serious problem because it makes construction investment projects risky.

If you want to improve project performance, focus on improving information flow

Information is the lifeblood of all project delivery. You can’t effectively work as a team to deliver a complex project without good, reliable, and accurate information.