Lean Beyond Hard Hats: Expanding Efficiency with Data-Driven Practices

Lean construction has transformed project management, emphasizing collaboration, waste reduction, and continuous improvement. Tools like the Last Planner System (LPS) have significantly improved outcomes. But what if Lean's impact could extend beyond construction teams? In today's digital age, data-driven decision-making is paramount. This blog explores how leveraging a data-centric approach, specifically through the DELTA Efficiency Assessment, unlocks Lean's full potential. By streamlining processes across all project teams, DELTA breaks down silos and empowers stakeholders with data insights, paving the way for inclusivity and project transformation.

The Challenge: Siloed Lean Implementation

While Lean construction has seen success, its benefits are often limited to construction teams. This leaves untapped opportunities for improvement in departments like administration, finance, and technology.

Expanding Lean Beyond Construction

Experience underscores the importance of inclusivity for successful Lean implementation. By broadening the application of Lean principles, greater benefits can be realized. To optimize project delivery, we must address the health of the entire data and digital ecosystem.

DELTA: A Data-Driven Approach

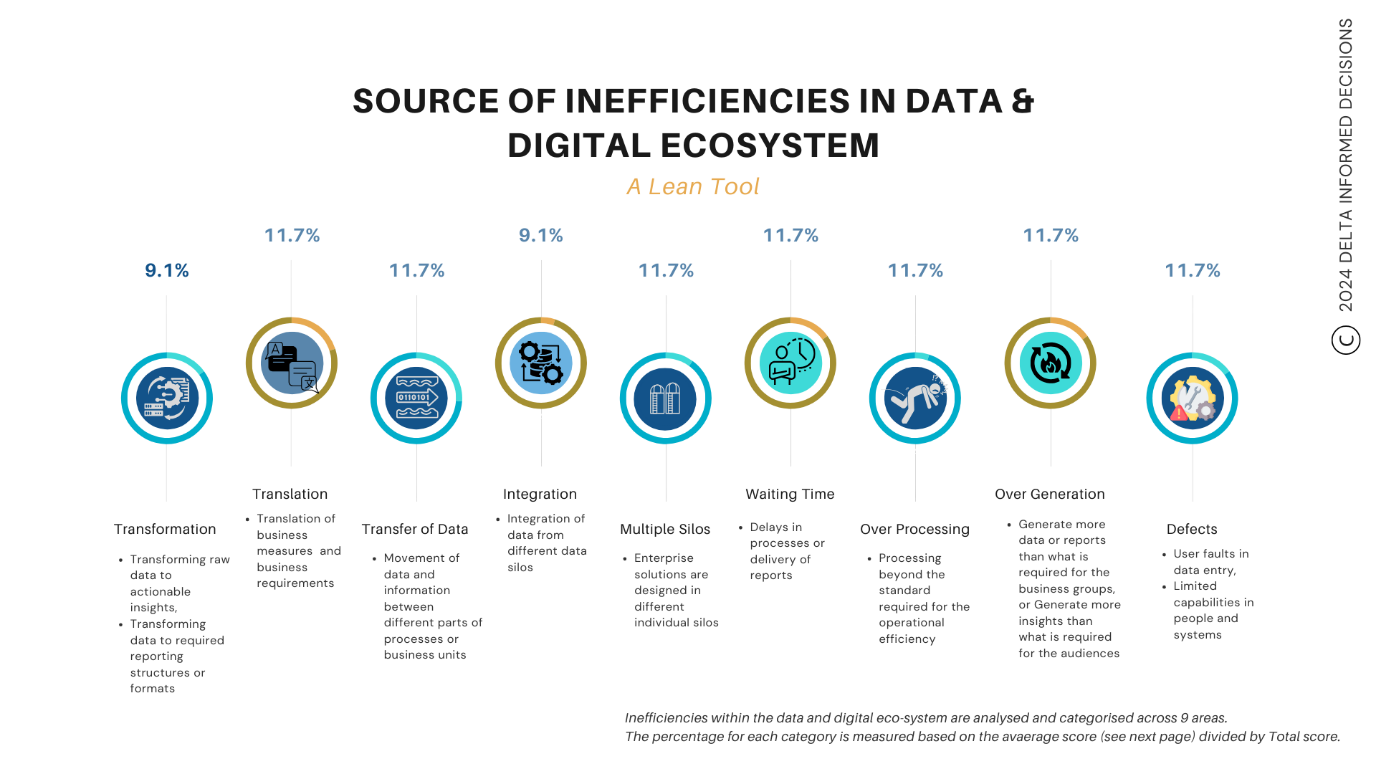

Building upon the foundational Lean TIMWOOD framework, DELTA adds key elements tailored to data-driven organizations. It provides a roadmap for identifying and addressing inefficiencies within the digital ecosystem, empowering leaders with data and insights for project excellence.

DELTA in Action: Addressing Inefficiencies

Let's delve into how DELTA addresses inefficiencies, aligning with TIMWOOD principles:

-

Transformation:

Converting raw data into actionable insights for effective Lean decision-making.

-

Translation of Data:

Ensuring collected data accurately reflects business needs and supports continuous improvement.

-

Data Transfer:

Enabling smooth information flow across departments for timely action.

-

Integration:

Bringing together data from diverse sources for informed project delivery decisions.

-

Multiple Silos:

Breaking down data silos for seamless data flow across systems.

-

Waiting Time:

Minimizing delays in data access to empower timely decision-making.

-

Over Processing:

Streamlining processes to eliminate unnecessary steps and optimize report generation.

-

Over Production:

Focusing on generating relevant data and reports that drive improvement.

-

Defects:

Improving data quality to reduce errors and ensure reliability.

The Importance of Data for Lean

Accurate data from LPS meetings is crucial for effective planning and collaboration in construction. However, the value of Lean is limited if key stakeholders are excluded. By streamlining Lean practices across all teams, organizations can maximize the benefits of Lean initiatives.

Case Study: DELTA in Action

A prominent construction firm implemented Lean and LPS principles within their construction team for ten months. Despite their efforts, they faced operational inefficiencies and declining trust from project sponsors. Inconsistent measurement and poor handling of LPS data hindered their ability to deliver value through Lean and LPS practices. Additionally, office and finance teams were not engaged in Lean/LPS methodologies. This lack of alignment across roles, ownership, and processes hindered the firm's overall Lean management efforts.

The DELTA Assessment Revealed:

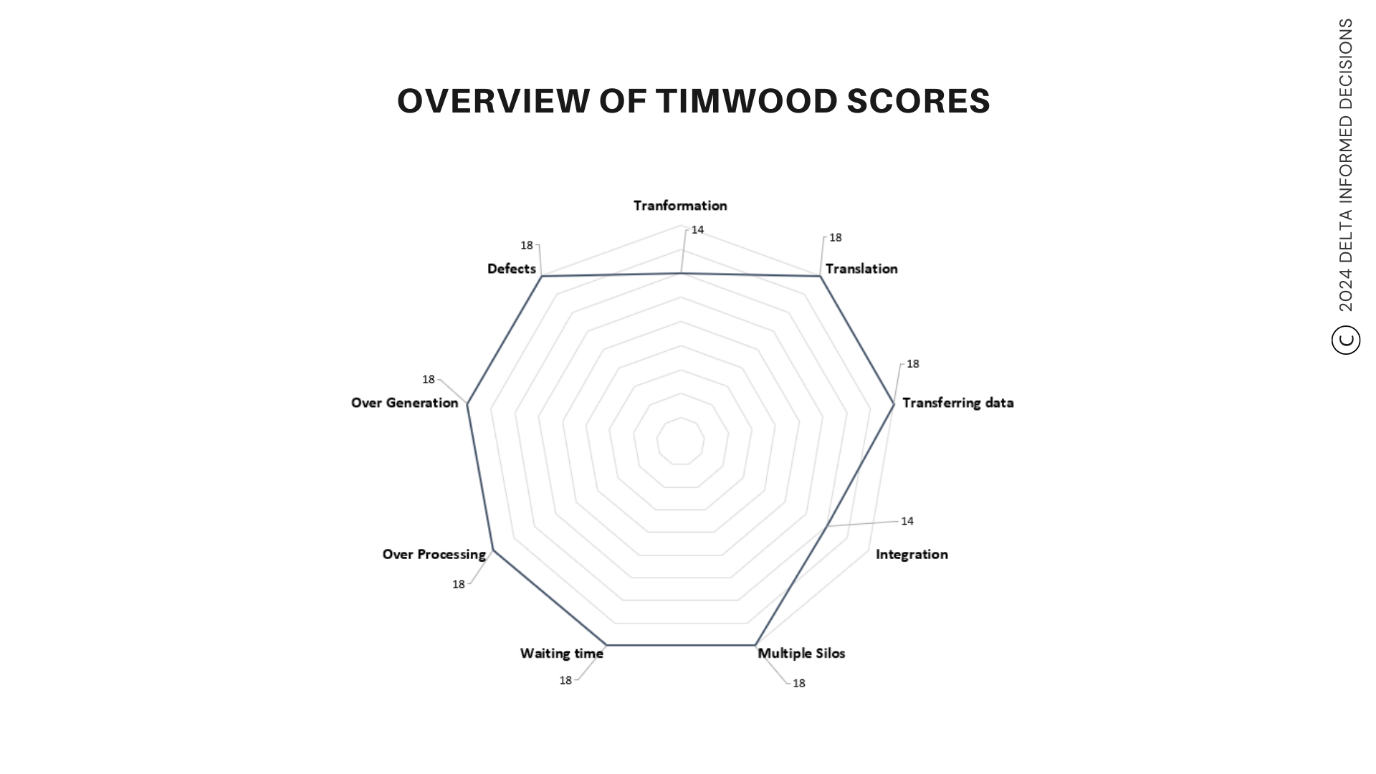

During the DELTA Efficiency Assessment, the analysis revealed concerning scores across all nine areas, indicating significant inefficiencies throughout the organization's data and digital ecosystem. Here's a breakdown of the key findings. For a visual representation of the key findings, please refer to figures 1 and 2 above.

-

Multiple Silos (11.7%): Fragmented data storage across various systems was identified as the most critical inefficiency. This siloed approach hampered information sharing and collaboration, hindering overall project delivery.

-

Translation of Data (11.7%) & Transferring Data (11.7%): High scores in these areas indicated difficulty aligning collected data with business needs and inefficient data flow between departments. This resulted in inaccurate or irrelevant information for decision-making and delays in accessing crucial data.

-

Waiting Time (11.7%), Over Processing (11.7%), and Over Generation (11.7%): These high scores suggested delays in accessing data, unnecessary processing steps, and generating excessive reports that overwhelmed stakeholders. These inefficiencies wasted resources and hindered timely decision-making.

-

Defects (11.7%): Data errors due to user input mistakes or system limitations were a significant concern, leading to unreliable information and potentially impacting project outcomes.

Solution Implemented:

The firm embarked on a mission to enhance inclusivity and expand Lean principles across the organization:

-

Breaking Down Silos: Integrating information from various systems for seamless data flow.

-

Improving Data Translation and Transfer: Aligning data collection and processing methods with business needs.

-

Optimizing Processes: Reviewing and streamlining workflows to eliminate unnecessary processing steps.

-

Enhancing Data Quality: Investing in training programs and technology solutions to improve data reliability.

Conclusion - The Power of Inclusive Lean

To successfully drive Lean across all project phases and achieve transformative results, a data-driven approach is essential. Tools like the DELTA Efficiency Assessment empower construction firms by promoting inclusivity, unlocking data-driven decision-making, enhancing project visibility, and engaging all stakeholders.

-

Promoting Inclusivity: DELTA fosters collaboration by engaging all project stakeholders in Lean practices and data-driven decision-making. This ensures everyone contributes to continuous improvement.

-

Unlocking Data-Driven Decision Making: The assessment empowers teams with access to reliable and timely data, enabling informed decisions throughout the project lifecycle. From planning and execution to tracking progress and managing risk, data becomes the foundation for success.

-

Enhancing Project Visibility: DELTA sheds light on inefficiencies within the data and digital ecosystem, providing clear insights for optimizing project delivery processes. By identifying bottlenecks and areas for improvement, the entire project team can work together to streamline operations.

-

Engaging All Stakeholders: By fostering a culture of data transparency and collaborative problem-solving, DELTA empowers all stakeholders to actively participate in project success. This shared understanding and ownership lead to better communication and project buy-in.

By cultivating a data-driven Lean approach across all project facets, construction firms can unlock the full potential of Lean principles. This empowers them to not only survive but thrive in today's competitive landscape. The DELTA Efficiency Assessment provides a valuable roadmap for achieving this transformation, paving the way for continuous improvement and project excellence.

Fahimeh Zaeri

Fahimeh Zaeri