Contact Information

info@leanconstructionblog.com

Related Webinars

all webinars

Last Planner and Takt Software Directory

This directory contains all of the Last Planner and Takt Software on the market. We encourage you to do your own research, set up a call with the vendors, and choose the software that fits your needs. This directory is meant to make it easy to find, compare, and make the decision on which software you can use.

What is a Takt plan?

Probably one of the most important questions out there is, what is Takt? Is it like CPM? Is it separate from the Last Planner® System? Does the word stand for something as an acronym? Well, you have come to the right place to find out. Let’s takt, ...oops, I mean take this journey together.

Introduction To Takt Planning

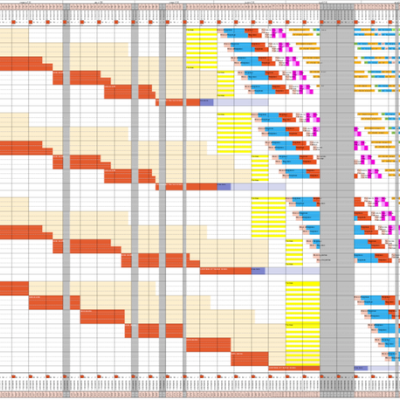

Takt Planning is a detailed one-page, one-process flow schedule that focuses on throughput, bottlenecks, and ultimately, creating flow. It is accompanied by Lean practices to be the most effective scheduling tool in the industry for construction because it creates stable construction environments, enables total participation, and provides a basis upon which to improve all aspects of construction.

Creating a Takt Plan

Probably one of the most useful outlines we can provide for Takt is the step by step outline for how to create one. We hope to help you visualize the process in this blog post. One of the best ways to get into this system is to create your first Takt plan, so let’s get started.

Leveling Construction Production with Takt

In Takt planning, there are currently no tools on the market that give you a process for identifying and leveling production. Just because you can create a pretty chart does not mean that you can make that happen in the field. If construction were that simple, this topic would not be worth writing about.

Takt Control = Production Control

Takt Planning and Takt Control (TPTC) is the most widely used standard production system for what we call Takt in the construction industry. In this publication I am diving deep into the second half of the system as there is extensive content on Takt Planning.

How Integrated Project Delivery Enhances Takt Planning Implementation Mission Bernal Care Complex Case Study

Takt planning and Integrated Project Delivery (IPD) have become increasingly common topics in regard to Lean Construction. The purpose of this article is to explore and evaluate how IPD enhances and facilitates the implementation of Takt Planning.

Takt is the New Tune – How to Develop a Takt Plan Based on a Collaborative Planning Process

Takt is about creating harmony between people contributing to a common cause – whether it is to perform a piece of music or construct a building

Location Based Management System & Takt Time Development for Construction Sites in France

Lean Construction has been developing in France since the 2010s, mainly under the impetus of specialized consultants for the largest general contractors.

How to begin, advance and thrive with takt production: A maturity model & takeaways from 24 Finnish cases

If you’ve engaged with lean construction lately, you’ve probably heard about takt production - if not already employed it.

An Introduction to Takt Time Planning

‘Takt time’ is a term used in manufacturing to describe pacing work to match the customer’s demand rate. ‘Work structuring’ is the practice of scheduling out work and is a part of designing a production system. Takt time planning then, is one method for work structuring around a set pace of work.

5 Steps To Takt Time Planning

As a foreword to the post, I think there are many ways one can execute Takt time planning (TTP). The fact that there isn’t much research on the topic in construction means that it is definitely an open question. Through some iteration and research, the five step method below is the best practice to Takt time planning so far.

What is the Takt Production Model?

In recent years, Takt Production has received a lot of interest in the construction and we are seeing more and more implementations around the industry. Takt Production comes from the aeronautical industry and its purpose is to stabilize and maintain rhythm of production.

A Brief History of Location-based Scheduling and Takt Time Planning

Location-based scheduling methods are not new. In some countries such as Finland, the adoption of line of balance schedules is widespread and used for decades. However, in the United States these schedules have remained unpopular.

Takt time planning - When the train falls off the tracks

Takt time planning is a great tool for aligning crews and creating flow on site. However, it’s still just a plan and it will inevitably fail at some point. One of the reasons for using takt time is not only to create flow, but also help pinpoint where the bottleneck is on site.

Introduction to Location Based Management System: CPM on Steroids Combined with Flowline Visualization

The Location-based Management System (LBMS) builds on decades of work on location-based scheduling methods. The first recorded utilization of location-based methods in vertical construction was in the Empire State Building.

A Deeper Look into LBMS Controlling System – Preventing Cascading Delays

In my previous post about LBMS, I mentioned that cascading delays can cause project duration increases of 10% or more. This blog article digs a bit deeper and explains what cascading delays are, why they happen in construction projects and how LBMS controlling can help to prevent them.

Introduction to Takt Time Production Planning

Takt planning has come into its own in the last few years. Takt is German word (Taktzeit Cycle) for establishing the “beat” or rhythm of a process. Companies including BMW, Sutter Health, and others have reported very positive results of implementing Takt planning.

The Last Planner ® System during the Finishing Phase in the World of Small Trade Partners

The Last Planner System (LPS) is a production planning and control system designed to produce predictable workflow and rapid learning in programming, design, construction and commissioning of projects. LPS has five main elements.

Construction 4.0 and The Future of Flow

Modern understanding of lean has evolved over several decades and is mostly based on the knowledge gained from the past experiences. However, in today's world new knowledge and developments are evolving very fast, which means that our today's ingrained understanding can tomorrow already be old.

Direct Work Efficiency: What Makes the Takt Production Matrix (TPM) so Valuable?

Production management, as we know, has been a hot topic within our industry for some time now. And we’ve looked at it from just about every angle. No doubt.

Leaning In: Construction Team Embraces Takt Planning on Neuroscience Research Building

A primary goal of Takt planning, in lean construction terms, is to create “flow.” In other words, the objective is for each project phase to progress in a logical sequence with no interruptions, delays, or bottlenecks.

Lean Simulation Game with BIM-based Progress Monitoring for Takt Control

BIM and Lean Construction are promising methods for improving the construction process, with BIM focusing on the product and Lean Construction on the process. Combining both methods can lead to further improvements.

Takt Planning on a 1 Billion Dollar Infrastructure Project

Takt Planning was implemented in two stages, first at the micro-level and then at the macro-level. Stage one work balanced the outflow, work-worker allocation, and distribution, and harmonized the pace of work.

Revolutionizing the Construction Industry with One-Piece Flow

The unique power of Lean lies in its ability to maximize quality and resource productivity by minimizing throughput time and Work-In-Process. A key element of this strategy is the implementation of one-piece flow.

Get Communication Flowing And Keep Your Jobsite Going

Coordination issues on a construction site can spread like wildfire. This comes as no surprise to anyone. Why? There are so many moving parts in any one given day/hour/minute during the life of any job.

The start of the takt production was boosted by Porsche and cruise ships

In the early 2010s, Aleksi Heinonen learned how to renovate all 1,500 hotel rooms on a cruise ship in two weeks. He thought that Porsche's lessons in takt production applied to the project could be of interest to builders.

A Lean-based Index To Predict and Prevent Delays in Construction Projects

In the pursuit of greater reliability and control over project deadlines, Lean Construction professionals are increasingly turning to location-based planning and takt-driven production. While traditional indicators like physical progress measure what has been done, they often fail to predict when a project will be completed.