Contact Information

info@leanconstructionblog.com

Related Webinars

all webinarsPreparing The Team to Implement 5S

I usually share with people that 5S is a countermeasure. It solves the problem of a workplace having no standard or stability from which to improve. This means that 5S is not the goal but merely a starting point for improvement.

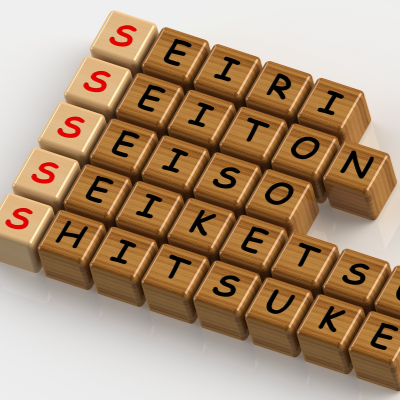

Introduction to the 5S System

This system was created by Ford and later improved upon by Toyota. Ford called it the CANDO system. CANDO is an acronym developed by Henry Ford to make the work area more organized and efficient.

Sort–the First “S”

Sort is to categorize all materials and remove what is unnecessary. The concept of sorting is simple. You simply remove all materials that are more than what is classified as the strategic amount for your job site. The good thing is that you get to decide what a strategic amount means to you.

Straighten–the Second “S”

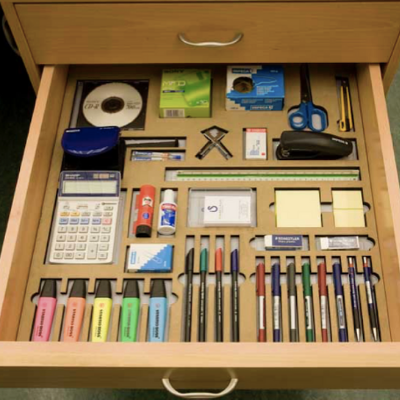

Straighten is to make sure that there is a place for everything, and everything is in its place. The only way to guarantee this is to think about the visual controls needed right at the beginning of the process.

Sweep or Shine–the Third “S”

Sweep is the activity of bringing your area up to a standard and then using that standard -daily - to inspect and keep that area clean.

Standardize–the Fourth “S”

Standardize is the activity of making Sort, Straighten, and Shine part of the project routines. When the general contractor realizes how much benefit they receive from doing 5S, they introduce other standards as statements.

Sustain–the Hardest “S” of All

Sustain is the hardest S of them all. This makes sense because of two main reasons. One, it encompasses all the other Ss. You should ask many questions that start with how we should sustain.

Keys and Tips to Implement the 5S Methodology

The 5S methodology was born at Toyota in the 60s under an industrial environment to achieve better organized, tidier, and cleaner workplaces to increase productivity and to obtain a better working environment.

6 Tips On How To Implement A Lean Office in the AEC Industry

A highly revered ex-Toyota consultant stated that most manufacturers seem focused on achieving a 35 to 40 percent productivity gain over three to five years as a measure of success in their current Lean efforts.

5S - Building A Lean Culture in the Field

How can 5S benefit the construction industry? It improves productivity, quality, safety and schedule. It is a core lean method to bring Lean thinking to frontline workers in the field or shop. It is simple. It costs almost nothing.

Increasing Job Satisfaction and Worker Retention through 6S (5S + Safety)

Perhaps the single greatest opportunity for management to demonstrate respect for all employees is through the company’s culture of safety and implementation of 6S in all aspects of the business and construction process.