Contact Information

info@leanconstructionblog.com

Articles By This Author

Benefits of Visual Management

This Post is the first of a series about Visual Management in Construction. The topics I will write about in the different posts will cover: a general overview and background, the meaning of VM, the benefits of VM.

The Big Room as a Visual Management concept in Last Planner® System

In this post we will talk about the importance of the Big Room as a tool and a key element of Visual Management to guarantee the success in the implementation and follow up of the Last Planner System.

The Power of Lean Visual Management in Construction

To understand the true impact that visual management has on the implementation of Lean Construction, we must go back to the origins of Lean. If you go to the basics of the Toyota Production System, you will see Visual Management everywhere.

10 Successful Keys to Implement Lean in Construction Companies

In this post we have compiled a set of good practices based on our own experiences that in general have worked when we have implemented Lean Construction at the company level. This post summarizes 10 years of experiences and both successes and difficulties have been considered.

The 5 Benefits of the Big Room with the Last Planner® System

The concept of “Big Room”, also known by the Japanese word “Obeya” is linked with the concept of co-location, which in Toyota refers to the practice of locating multidisciplinary teams in the same place to improve communication and creativity.

5 Key Ideas to Make Your Lean Implementation More Successful

As a trainer and consultant of Lean Construction, I have always been passionate about the human side of Lean. I have been observing the behaviour of people in a lot of companies regarding the cultural changes that comes with implementing Lean.

Teaching Lean Construction I: Pull & Flow

According to Tommelein et al.1, workflow can be characterized in several different ways. In manufacturing, it is defined by stationary machines with partially completed products being transported from one to the next. In construction, the products being built tend to be stationary, whereas crews of various trades move from location to location.

Teaching Lean Construction II: Last Planner

Glenn Ballard and Greg Howell developed the Last Planner System of Production Control throughout the 90s1. At the same time, Lauri Koskela was working on developing a theory of production which provided the theoretical framework for the LPS2.

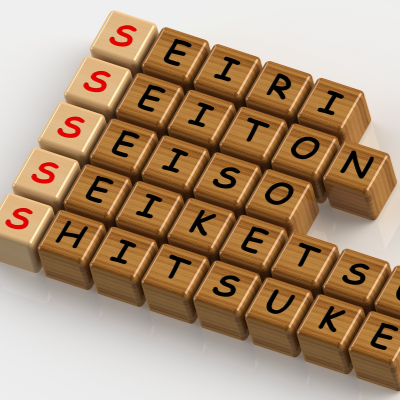

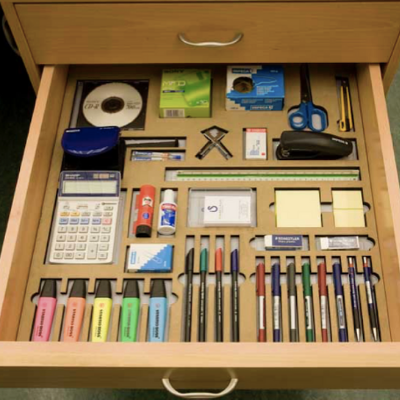

Keys and Tips to Implement the 5S Methodology

The 5S methodology was born at Toyota in the 60s under an industrial environment to achieve better organized, tidier, and cleaner workplaces to increase productivity and to obtain a better working environment.

6 Tips On How To Implement A Lean Office in the AEC Industry

A highly revered ex-Toyota consultant stated that most manufacturers seem focused on achieving a 35 to 40 percent productivity gain over three to five years as a measure of success in their current Lean efforts.