Industrialization in Construction: Promise vs. Reality

Industrialized construction (IC) is often presented as a pathway to higher productivity, cost efficiency, and better quality. Standardization, prefabrication, and stronger supply chains are central to this vision.

In Colombia, however, industrialization is still in its early stages. Prefabrication is limited, standardization remains uneven, and projects continue to rely heavily on labor-intensive processes. The sector has begun to move in this direction, but overall maturity is low. The key question is how Lean principles can support and accelerate this adoption in a market that is still developing its capabilities.

A Closer Look at the Study

We addressed this question in our paper presented at the 32nd Annual Conference of the International Group for Lean Construction (IGLC 2024). We conducted twenty semi-structured interviews with professionals working in some of Colombia's largest firms, including BIM managers, Lean managers, designers, project managers, and site leaders (León et al., 2024).

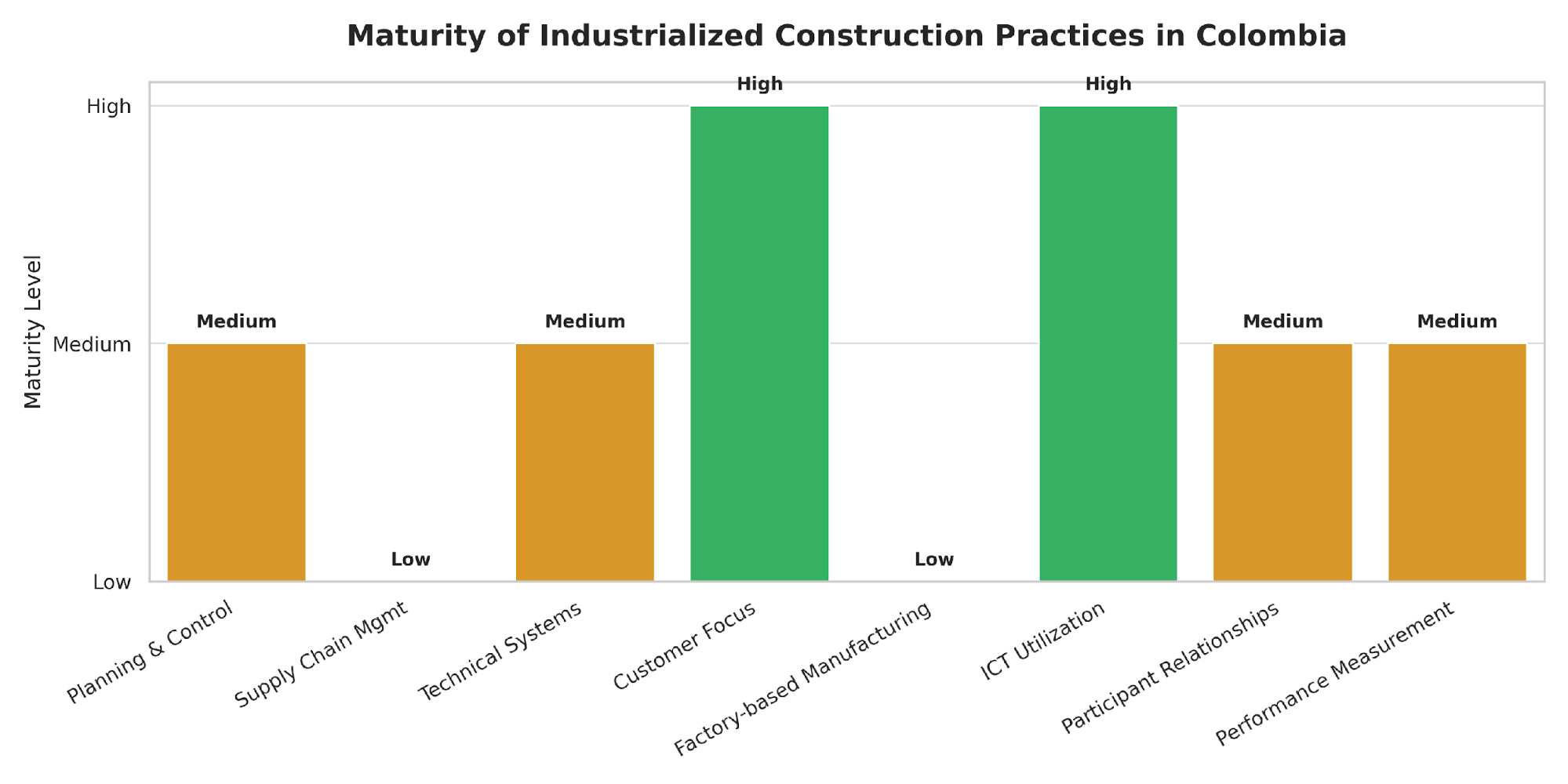

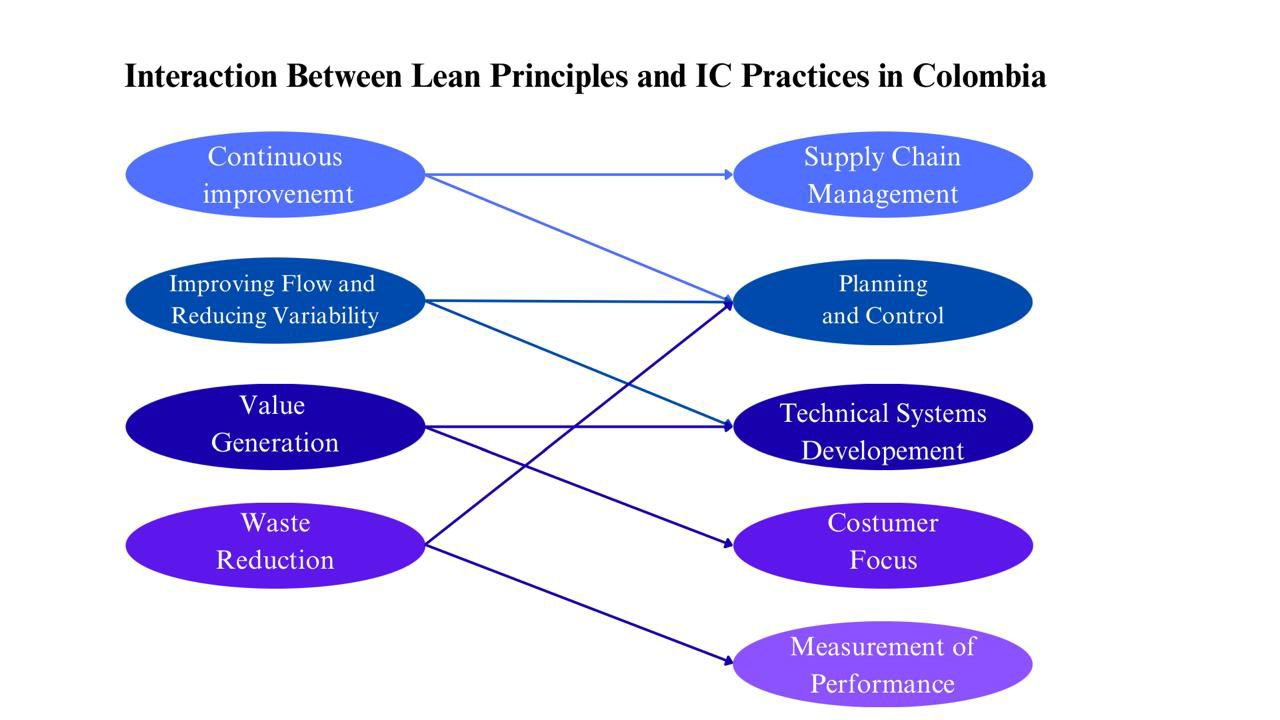

To analyze the results, we relied on Lessing's framework of eight IC practices (Lessing, Jerker, 2015) and compared them with four Lean principles: continuous improvement, improving flow and reducing variability, value generation, and waste reduction (Koskela et al., 2002). This approach provided a snapshot of IC maturity in Colombia and revealed where Lean principles could play a decisive enabling role.

Where Colombia Stands Today

Our findings show a sector that is beginning to change. Interest in IC is real, and some firms are testing practices in planning, coordination, and digital information management. Customer integration and technology use appear relatively more advanced, with companies piloting collaborative platforms and common data environments.

Other areas lag behind. Prefabrication is still rare, technical system standardization is weak, and most work continues to be carried out on site. Of the eight IC practices we studied, only two have reached a more developed stage in Colombia. The result is a fragmented picture: strong intentions but limited maturity.

Barriers to Industrialization

Several consistent barriers emerged during the interviews. The first is financial. Industrialization requires higher upfront investment in design and technology, which can deter firms operating with narrow margins (León et al., 2024).

Fragmented supply chains and short-term contracts are another barrier. They limit opportunities for integration and prevent the creation of stable flows. Design processes also create problems, since conventional approaches are not well aligned with industrialized production, resulting in late changes and rework.

Cultural resistance and gaps in knowledge and training slow down adoption further. Many practitioners lack experience with industrialized methods and research investment remains limited. Finally, very few firms systematically measure productivity, cost, or waste, which makes it difficult to demonstrate the benefits of IC.

How Lean Can Help

Lean principles offer practical ways to address these issues. Continuous improvement routines such as structured Last Planner meetings support learning and create the discipline needed for supply chain integration and new technology adoption. Standardized workflows and clearer information flows improve planning reliability and reduce variability (Ballard & Howell, 2003).

Placing more emphasis on value generation reframes industrialized solutions as a way to deliver better outcomes for clients. Waste reduction provides a practical entry point. Once firms begin to measure rework and inefficiencies, they can act on them, and this momentum creates space for more ambitious industrialization efforts.

Opportunities Ahead

Although IC maturity is still low, the combination of Lean and IC provides clear opportunities. Firms can begin with targeted pilots, for example creating a standard detail library for repetitive components, testing a single prefabricated element with defined performance criteria, or applying takt planning in one area of production.

When these pilots are paired with Lean routines that stabilize flows and track performance, they can build confidence, reduce uncertainty, and demonstrate tangible benefits. Over time, this approach improves productivity, strengthens supply chain integration, and reduces waste. Lessons learned in Colombia can also inform other Latin American markets that share similar levels of maturity.

Final Thoughts

Colombia's construction industry is interested in industrialization but has not yet reached maturity in most practices. Lean principles provide the scaffolding to stabilize processes, standardize methods, and scale these efforts.

As we showed in our IGLC 2024 paper, Lean and IC should be understood as complementary strategies. Industrialization without Lean risks being costly and fragmented. Lean without industrialization risks stagnation. Together, they provide a pathway toward more predictable, productive, and sustainable construction in Colombia and in other developing markets.

Nelly García López

Nelly García López William León

William León Jose A. Guevara

Jose A. Guevara