In construction, productivity is often hindered by fragmented logistics, unpredictable material deliveries and inefficient workflows. Coordinating the inflow of materials and the outflow of waste demands careful planning to ensure efficient logistics on-site. One promising solution that is gaining traction is material kitting, a logistics strategy where materials are pre-sorted into kits and delivered just-in-time (JIT) to the point of use. Research shows that kitting can improve on-site work performance, especially when paired with centralized logistics and proper planning [1].

What is material kitting and why does it matter?

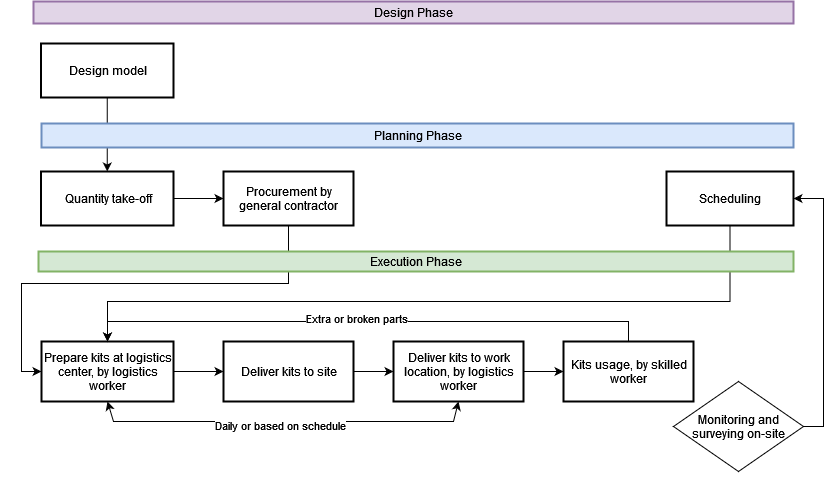

Kitting is a material supply system that is employed to group different components into a package according to the assembly schedule [2]. Materials can be kitted task-based or location-based. Instead of bulk deliveries that require sorting and handling on-site, kits arrive tailored to the task, reducing time spent searching for parts which minimizes disruptions to work. This approach has been widely used in manufacturing and is being adapted for construction projects. The practice supports a controlled material flow; kits arrive in a JIT manner, are used on-site and any leftover or damaged parts can be returned or reused elsewhere which contributes to reverse logistics integration. Figure 1 illustrates the kitting process.

In a comparative study of four renovation projects, researchers found that kitting improved workplace utilization, labor productivity and schedule adherence. With this practice, the workers focus on their core tasks instead of spending valuable time searching for or transporting materials on-site. For example, during plumbing and tiling phases, projects using kitting were significantly faster at task completion compared to traditional logistics models [1]. Moreover, by delivering kits directly to their point of use, it is possible to reduce the congestion on the job site which allows workers to move more efficiently. It can also minimize the risk of material damage that can occur during excessive handling or on-site storage.

What makes kitting work?

The method has several benefits and requirements that make it effective in improving construction efficiency. Kitting is most effective when supported by:

- Centralized procurement: Materials are sourced and managed centrally ensuring consistency and reducing waste.

- Consolidation centers: Kits are prepared off-site that allows for pre-assembly and quality checks.

- Digital planning tools: Accurate Bills of Materials (BOM) and updated schedules are essential for timely kit preparation and delivery.

- Subcontractor alignment: Commitment to the logistics model ensures smooth coordination across trades.

It was also noted that kitting can complement takt production by enforcing rhythm and reducing external variation which are some of the key principles in Lean Construction [3]. Moreover, the results from the studies on kitting [1][3] support the broader conclusions drawn by Hamzeh et al. [4], who demonstrated through simulation that logistics centers can reduce site-level inventory needs and improve supply chain responsiveness. Both lines of research highlight the value of centralized logistics, material aggregation and JIT delivery in managing variability and enhancing on-site productivity. Together, logistics centers, takt production and kitting are complementary strategies that support lean and flow-efficient construction operations.

Challenges and considerations

Implementing kitting requires upfront effort in planning and coordination. Management must forecast material needs well in advance and maintain clear communication with logistics providers. Some tasks, especially those involving large or custom components, may not benefit as much from kitting. Additionally, the success of kitting depends on the commitment of all project stakeholders.

A common pitfall observed in early implementations is an overemphasis on resource efficiency such as optimizing labor or material usage at the expense of flow efficiency [5]. In kitting-based systems, the sequence of work (e.g., apartment order or task flow) must be carefully maintained to ensure smooth material delivery and installation. Deviating from the planned sequence can disrupt the entire logistics chain leading to delays and rework. This highlights the importance of designing production systems that prioritize stable and predictable flow over isolated efficiency gains.

Final thoughts

Kitting logistics offers a practical way to enhance productivity and flow on construction sites. By reducing material handling and aligning deliveries with task execution, it supports Lean principles and improves overall project performance. As more companies explore industrialized logistics, kitting stands out as a scalable and impactful strategy worth considering. Embedding material kitting into digital logistics models could enhance the alignment of incoming deliveries, on-site handling and outbound flows as well as offer a practical strategy to reduce inefficiencies and improve resource utilization across projects.

Acknowledgements

Special thanks to Otto Alhava, Fira Rakennus Oy as well as Ari Viitanen from Carinafour for providing access to project data and sharing expert insights that greatly enriched the research and practical understanding of kitting logistics in construction.

Müge Tetik

Müge Tetik