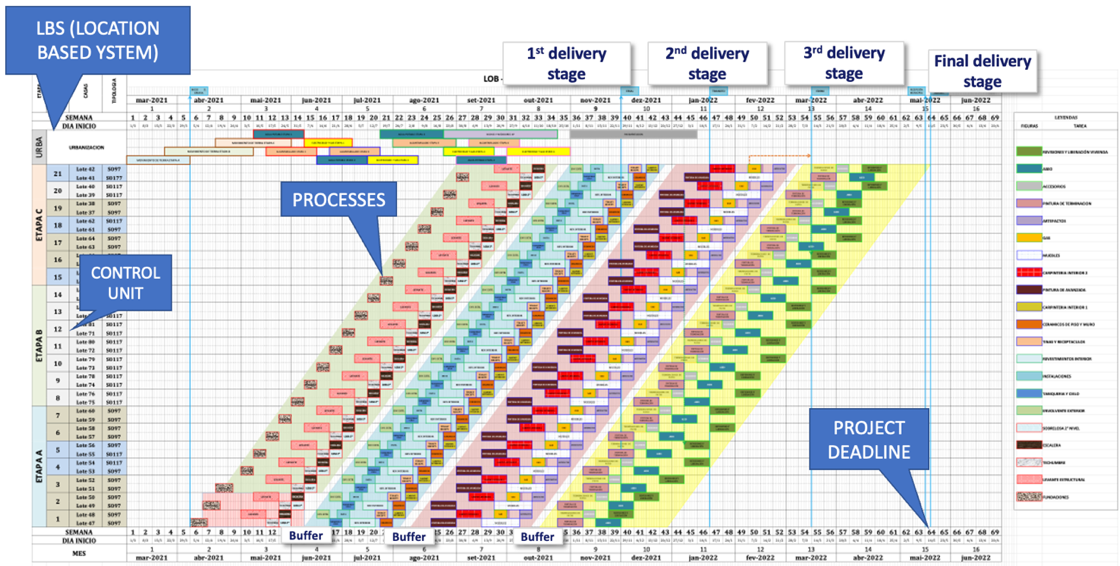

In the pursuit of greater reliability and control over project deadlines, Lean Construction professionals are increasingly turning to location-based planning and takt-driven production. While traditional indicators like physical progress measure what has been done, they often fail to predict when a project will be completed. That’s where our proposed Deadline Deviation Index (DDI) comes in — a practical and data-driven tool that integrates Line of Balance (LOB) and Rhythm Deviation to track and anticipate schedule performance in construction projects.

Moving Beyond Physical Progress

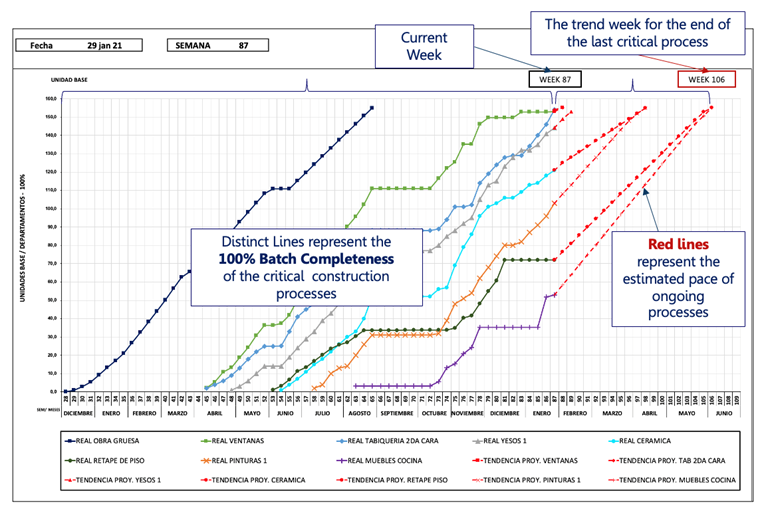

Traditional project tracking methods rely heavily on earned value and physical progress. However, these are lagging indicators — useful for post-mortem reviews but limited in real-time decision-making. In contrast, Lean Construction promotes flow reliability, takt control, and process-based measurement. Our work shows that combining LOB with rhythm deviation unlocks powerful insights about how production pace affects final delivery.

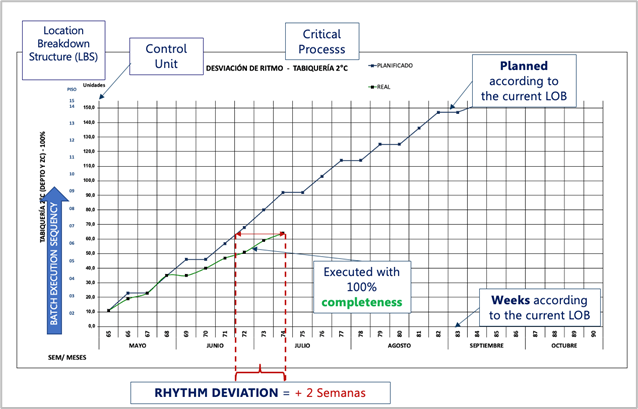

The Value of Monitoring Rhythm

Rhythm Deviation measures the gap between planned and actual execution dates of critical tasks — typically tracked in weekly batches. By visualizing these deviations, teams can quickly identify where work is ahead or falling behind, and what impact this may have on other dependent tasks.

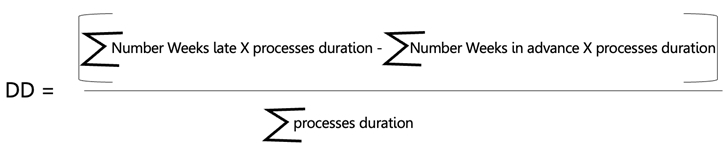

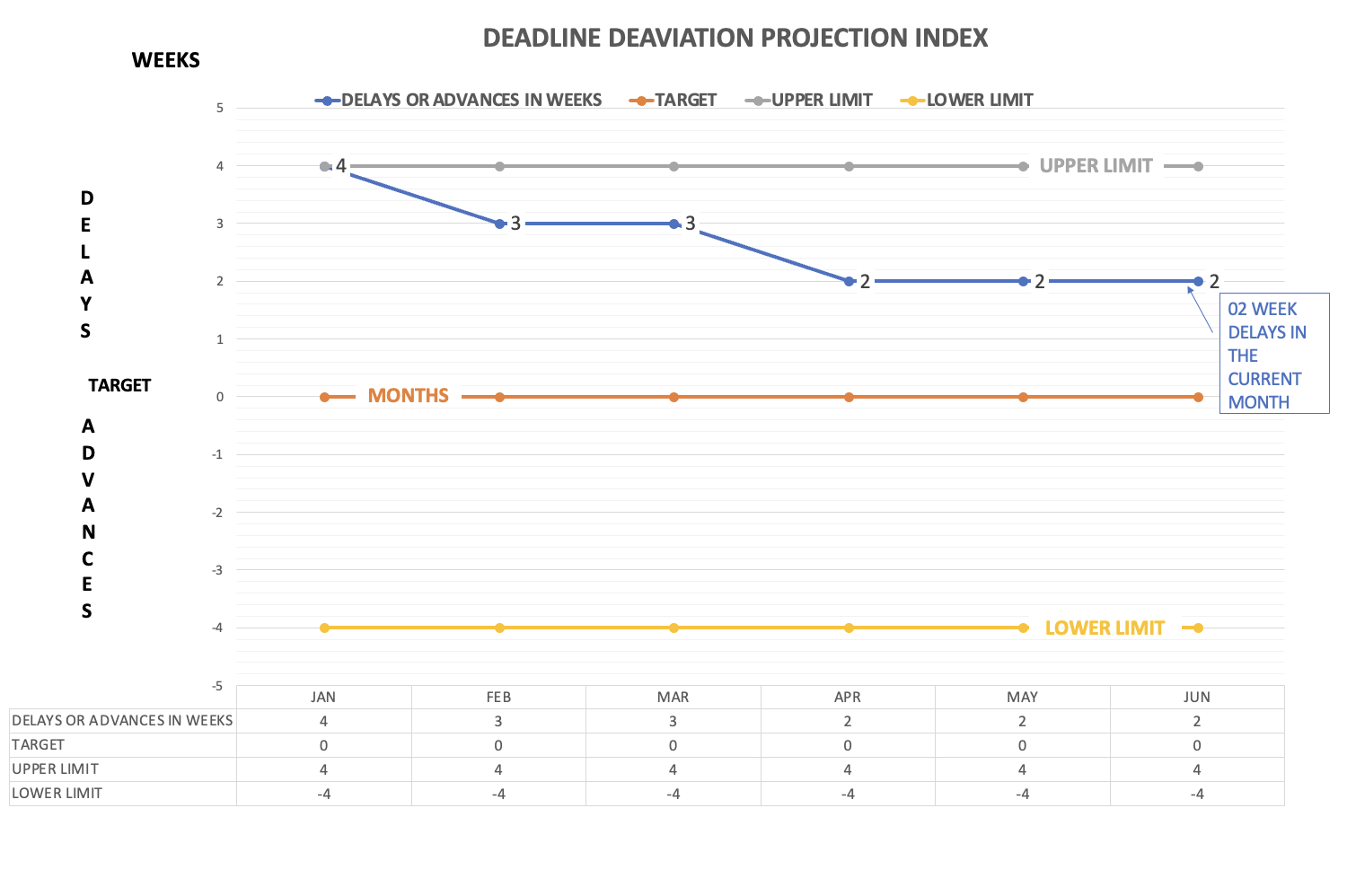

Building The Deadline Deviation Index

The Deadline Deviation Index (DDI) aggregates rhythm deviations across critical activities and compares them to total project duration. The result is a simple but powerful number that signals whether a project is ahead or behind schedule — and by how much.

The DDI enables project teams to establish early warning systems for planning adjustments. Weekly data collection is aligned with lookahead meetings, minimizing extra effort and maximizing insight.

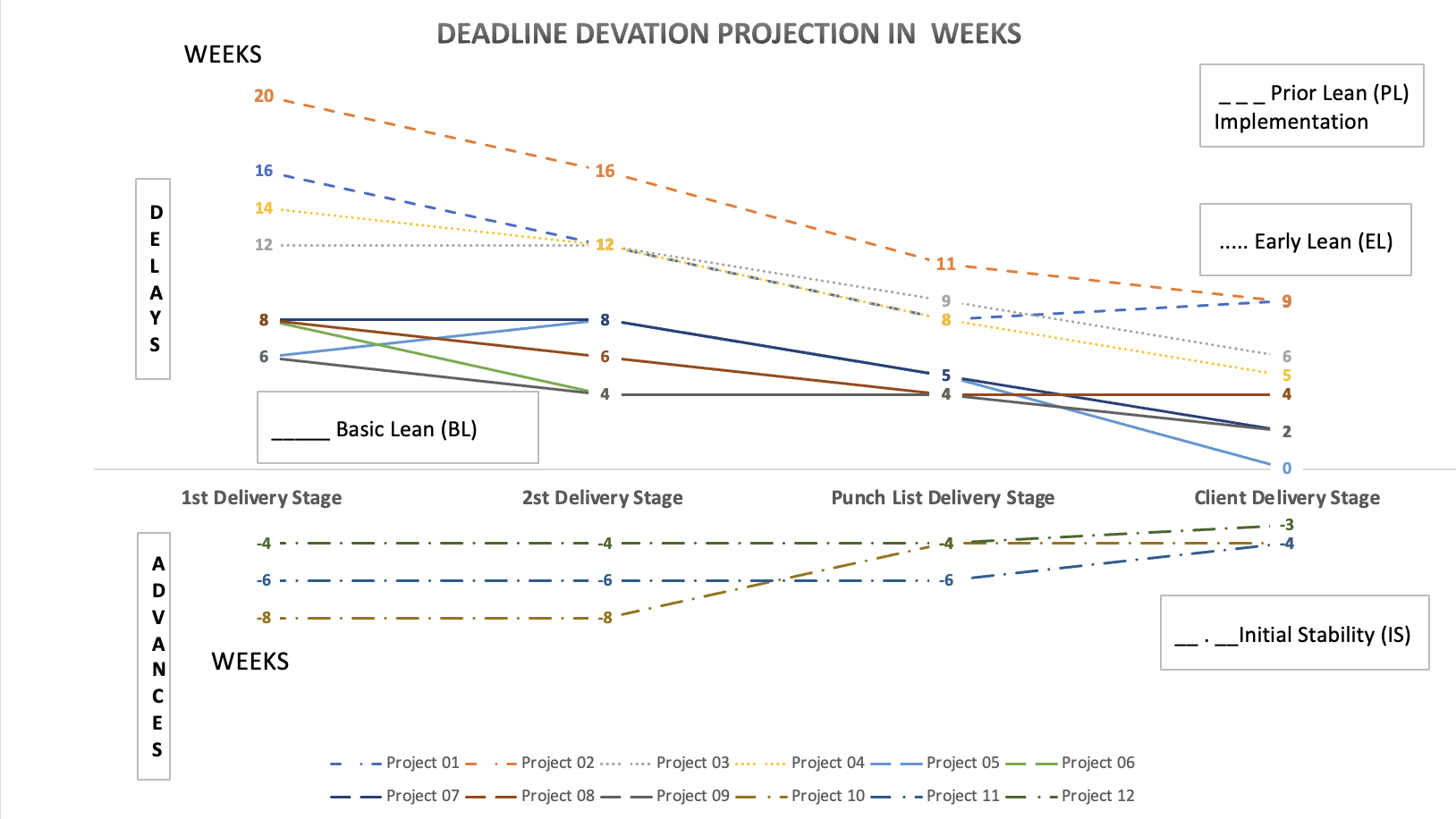

Tested Across 12 Projects

The DDI was piloted in 12 housing projects in Brazil, Chile, and Uruguay, with varying levels of Lean maturity. Projects with more advanced Lean implementation (Last Planner System, LBPC, and rhythm tracking) showed lower variability in deadline performance and greater predictability at each delivery stage.

Why It Matters

This approach allows teams to move from reactive to proactive — identifying delays before they impact final delivery. The DDI offers Lean practitioners a simple yet actionable tool to:- Track flow disruptions early

- Enhance lookahead planning with real-time data

- Communicate performance trends clearly across stakeholders

- Drive accountability in batch completion and takt control

As Lean Construction evolves, tools like the Deadline Deviation Index help turn

principles into action — enabling smarter decisions, smoother flow, and better project

outcomes.

Want to learn more or apply the DDI to your projects?

Feel free to reach out to the authors at marcus@ldconsulting.com.br or visit www.ldconsulting.com.br

Marcus Sterzi

Marcus Sterzi