Ever felt like project issues always lead to finger-pointing, rather than real solutions? In the dynamic and often fragmented world of construction, it's easy to blame individuals when things go wrong. But what if the problem isn't the person, but the system they're working within?

This is a crucial "aha" moment that lean construction aims to deliver, and one powerful tool for this realization is the Repair-Co Game.

Initially designed to highlight the systemic nature of inefficiencies in organizations, the Repair-Co Game has now evolved into an even more impactful learning experience. An expanded version, recently tested with students and industry professionals across India and the USA, demonstrates how this simple simulation can introduce the power of lean tools for identifying root causes and effective countermeasures.

What is the Repair-Co Game, Anyway?

Imagine a repair company dealing with customer service requests. Customers call a call center, logistics dispatches a repairperson, and the repairperson follows a set route. Participants are given a scenario where the expected daily repair visits aren't matching the actual visits.

The first phase of the game involves brainstorming reasons for this variability. Crucially, it then guides participants to differentiate between problems caused by the "repairperson" (the individual) versus the "system" (management, processes, tools). The powerful takeaway? Most reasons for varied performance are outside the repairperson's control, fundamentally due to a fault in the system. It's a vivid demonstration that often, the system needs fixing first, with the collaboration of those doing the work.

From Awareness to Action: The Power of Lean Tools

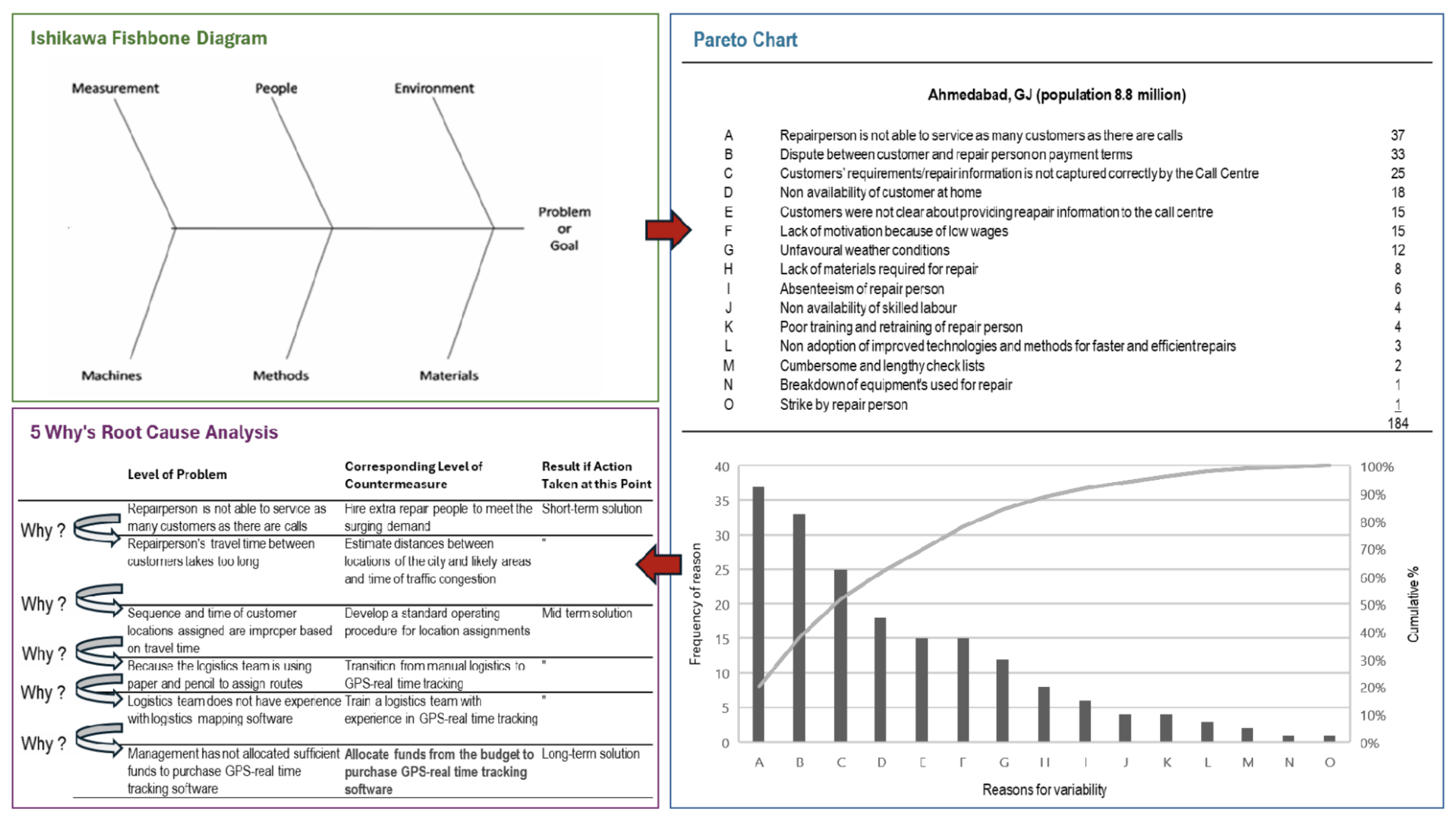

While the original Repair-Co Game stops at this crucial realization, the extended version takes learning a step further (Figure 1). It introduces participants to a sequence of three vital lean tools that can systematically solve organizational challenges:

- Ishikawa Fishbone (Cause-and-Effect) Diagram: After brainstorming potential causes, participants categorize them under six key areas: Measurement, Manpower, Environment, Machines, Methods, and Materials. This structured approach helps uncover causes that might otherwise be overlooked, like inaccurate performance measurement.

- Pareto Chart: Not all causes are created equal. The Pareto Chart visually ranks the identified causes by their frequency or impact, helping teams focus their limited resources on the "vital few" causes (typically 20%) that contribute to the "trivial many" (80%) of the problem.

- 5 Whys Root Cause Analysis: Once the primary causes are identified, the "5 Whys" technique systematically drills down to the ultimate root cause by repeatedly asking "Why?". This prevents superficial fixes and ensures a permanent solution by addressing the underlying issue.

These tools, when used collaboratively in a "Big Room Meeting" setting, enable a continuous improvement cycle (Plan-Do-Check-Act or PDCA), allowing countermeasures to permanently resolve problems at their core.

Real-World Insights: Context Matters!

The extended Repair-Co Game was piloted with graduate students at Texas A&M University and CEPT University, as well as professionals at URC Construction in India. A fascinating aspect of these trials was the introduction of two different contexts: a large city and a small town.

It became evident that solutions are indeed context-dependent. For instance, "traffic" emerged as a primary cause of variable performance in large cities, leading to countermeasures like optimized routing or hiring more repairpersons for specific zones. In contrast, small towns frequently highlighted "insufficient customer demand" and "non-availability of skilled manpower" as key issues. This reinforced the idea that there's no "one-size-fits-all" solution and managers must systematically investigate causes within their specific context.

🏙️ Large City Context

- Primary issue: Traffic congestion

- Countermeasure: Optimized routing

- Solution: Zone-specific hiring

🏘️ Small Town Context

- Primary issue: Insufficient customer demand

- Challenge: Non-availability of skilled manpower

- Solution: Context-specific strategies

The Takeaway for Your Projects

The Repair-Co Game, especially its extended version, is a powerful roadmap. It not only creates an "aha" moment about system-level problems but also provides hands-on experience with practical lean tools. By fostering collaborative brainstorming and systematic analysis, it helps teams move beyond blame and towards effective, sustainable solutions for continuous improvement.

If your construction team is looking to truly embed a problem-solving culture and leverage the power of lean, experiencing the Repair-Co Game could be your next breakthrough!

References

- Mossman, A. (2020). "Repair-Co" (PowerPoint slides), The Change Business.

- Prabaharan, R., Devkar, G., Rybkowski, Z. K., & Kannimuthu., M. (2024). The Repair-Co Game: A roadmap to demonstrate the importance of problem-solving capabilities of Lean tools. In D. B. Costa, F. Drevland, & L. Florez-Perez (Eds.), Proceedings of the 32nd Annual Conference of the International Group for Lean Construction (IGLC32) (pp. 1303-1313). doi.org/10.24928/2024/0211

- Seddon, J. (n.d.). Vanguard Consulting, https://beyondcommandandcontrol.com, January 13, 2024.

- Seddon, J. (2020). "Bursting bureaucracy in home repairs" (podcast), https://beyondcommandandcontrol.com/get-connected/john-seddons-podcasts/busting-bureaucracy-in-home-repairs/, January 13, 2024.

- Bono, E. (n.d.). "Six Thinking Hats." https://www.debonogroup.com/services/core-programs/six-thinking-hats/, February 10, 2024.