The offsite construction market continues to grow as it provides practitioners and stakeholders with higher quality, speedy construction, and less waste. These benefits, however, are not risk-free. Offsite construction brings together a variety of complex and connected activities involving suppliers, logistics companies, manufacturers, and onsite contractors [1]. Managing these activities properly is highly important because when they are not handled well, it can hinder the realization of these benefits, while also leading to extra costs, delays, and a lack of satisfaction among stakeholders [2].

Lean tools, such as Kaizen, Heijunka, Just-in-Time, One-piece flow, and Poke a yoke, are often viewed as useful tools for offsite construction projects. They help manage tasks, boost productivity, reduce waste, and improve quality [3]. Additionally, the Lean approach can streamline processes through a method known as Value Stream Mapping (VSM), which helps eliminate non-value-added activities and focus on delivering value to the customer. Furthermore, project managers interested in lean practices usually perform a future VSM where they propose potential solutions to mitigate bottlenecks and reduce both production lead time and processing time. The future VSM serves as a theoretical solution that highlights the benefits of applying lean practices to a specific process or activity. In actual practice, applying these methods requires sophisticated tools to control the process and perceive the benefits of the lean approach.

On one hand, digital technologies, such as building information modeling (BIM) and smart contracts, offer the opportunity to implement lean practices in offsite construction. BIM tools enhance the visualization of building components, provide accurate quantity take-offs, and link each element to its metadata (e.g., supplier, installing location, and element type) [4]. On the other hand, smart contracts offer a structured, straightforward method for executing virtual tasks. In the context of lean practices, these virtual tasks can include digital Kanban and digital Andon. Consequently, the combination of BIM and smart contracts provides a comprehensive strategy for putting lean practices into action and realizing their intended benefits.

Practical Example

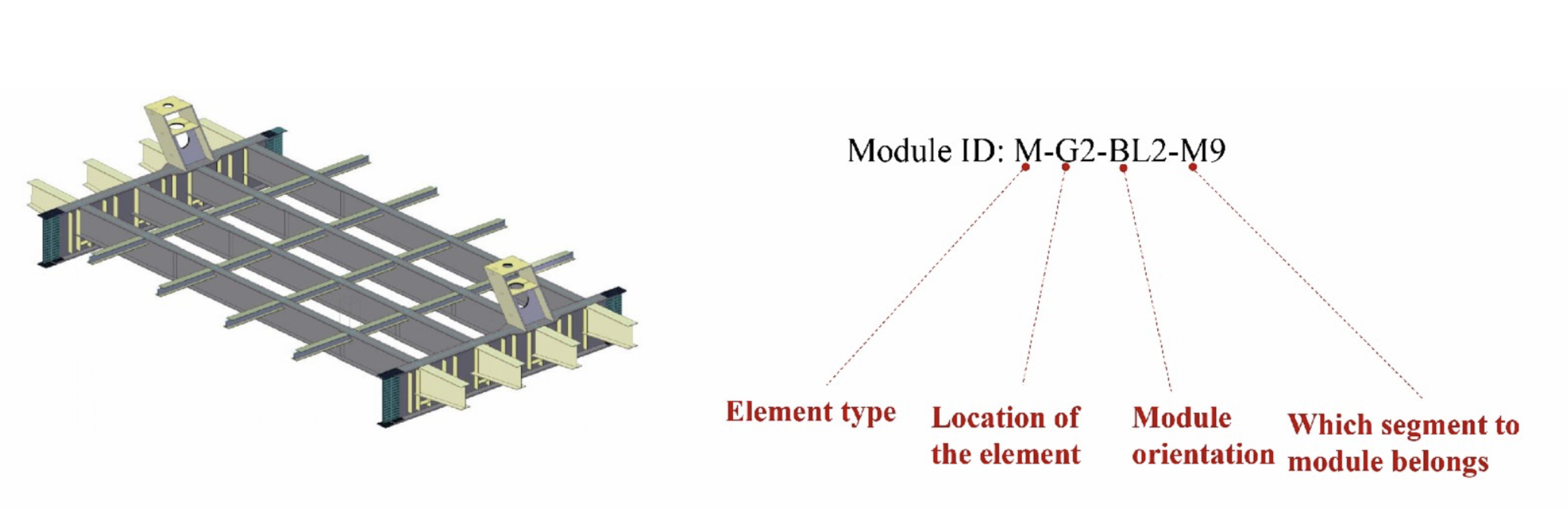

In a study conducted by the authors [5], a practical case study for applying BIM and smart contracts was introduced as a proof of concept. The case study illustrates the construction of a cable-stayed bridge. This bridge involves a variety of offsite processes, including: 1) the fabrication of the main and cross girders; 2) the assembly of steel modules in the yard; 3) the fabrication of precast slabs to be placed on top of the steel modules. Figure 1 shows a sample of created BIM models for a manufactured steel module. Every component in the model is marked with an ID that will be used in the smart contract system. The component ID specifies the component type and installation location.

The created BIM models were integrated with a smart contract to implement lean practices, including the following:

- One-piece flow: the system allows each station operator to request products as needed, without relying on a fixed schedule;

- Heijunka: the system levels out the process by reducing the inventory between stations using Just-in-Time approach;

- Quality at bay: The system allows participants to submit a notification to other operators when a defect is discovered. This notification includes the element ID, location, description, and degree of deficiency, using what is referred to as Digital Andon.

- Poke a yoke: any submitted quality issue, and how it was solved is stored in the system transaction part.

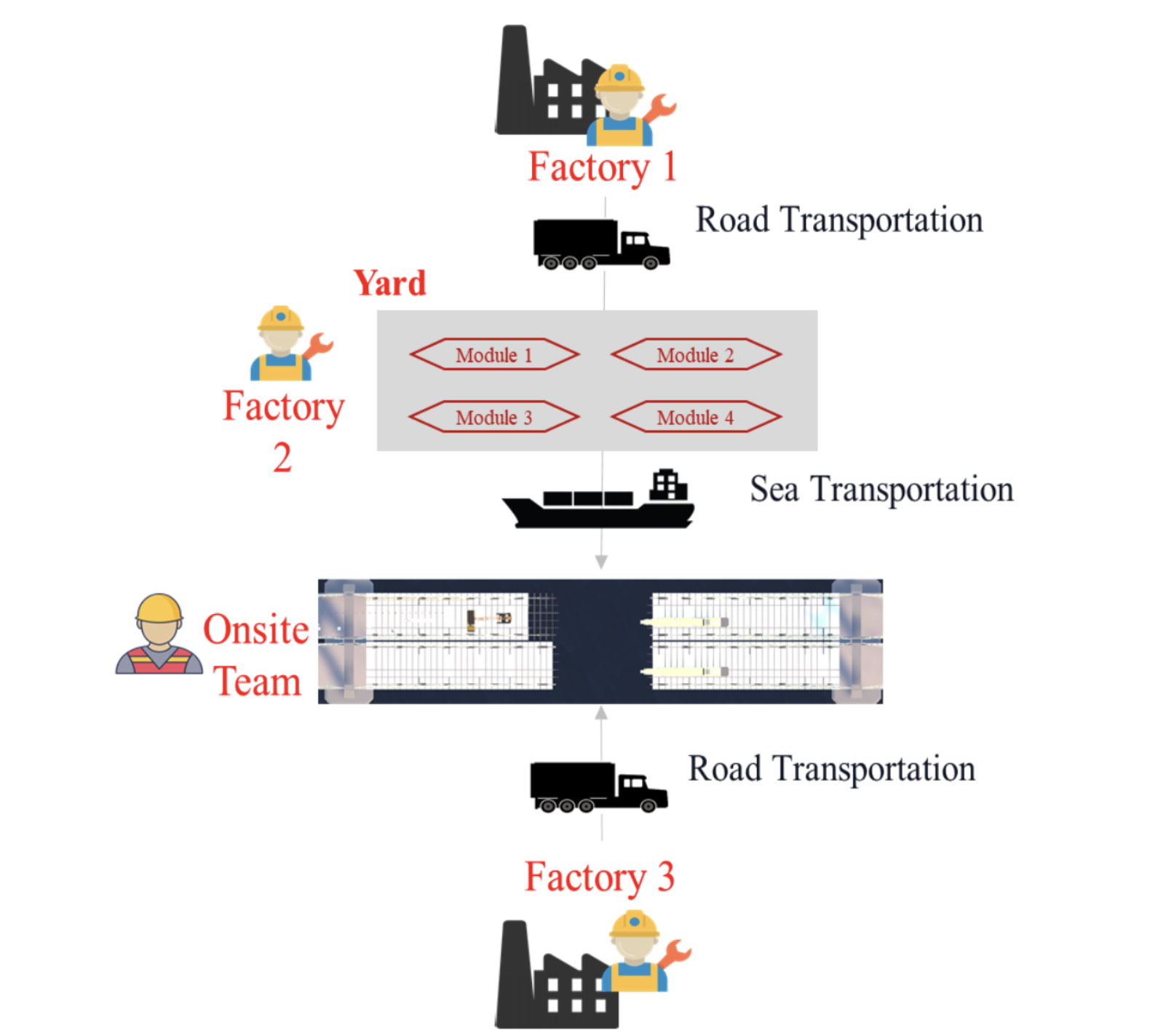

The created smart contract comprises many operators. Figure 2 illustrates the operators included in the network. Operator one is responsible for the fabrication of the steel girders, and Operator two is responsible for assembling these steel girders into modules. Operator three is responsible for the onsite works, and Operator four is in charge of the fabrication of precast slabs. Three main transportation routings are included in the system: transporting the steel girders from the factory to the yard by truck, shipping modules from the yard to the bridge by ships, and trucking the precast slab to the bridge deck from the offsite slab construction facility.

On the developed smart contract, many transactions (i.e., features) were available for the operators, including the following: 1) submission of a request for more elements, specifying the quantity and elements IDs; 2) submission of the needed elements by the corresponding operator and update of the ledgers on the system; 3) notify any quality issue (Andon) by an operator; and 4) query of any submitted defect resolution (mistake proofing).

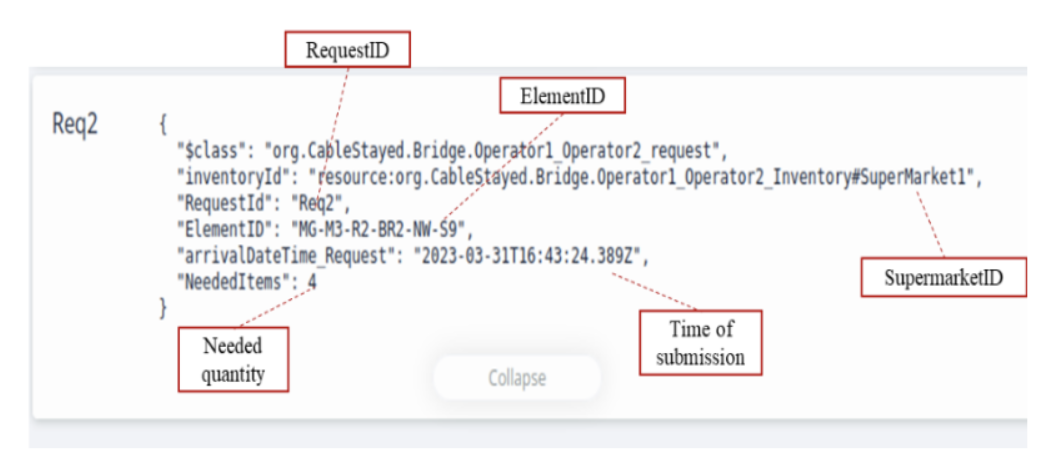

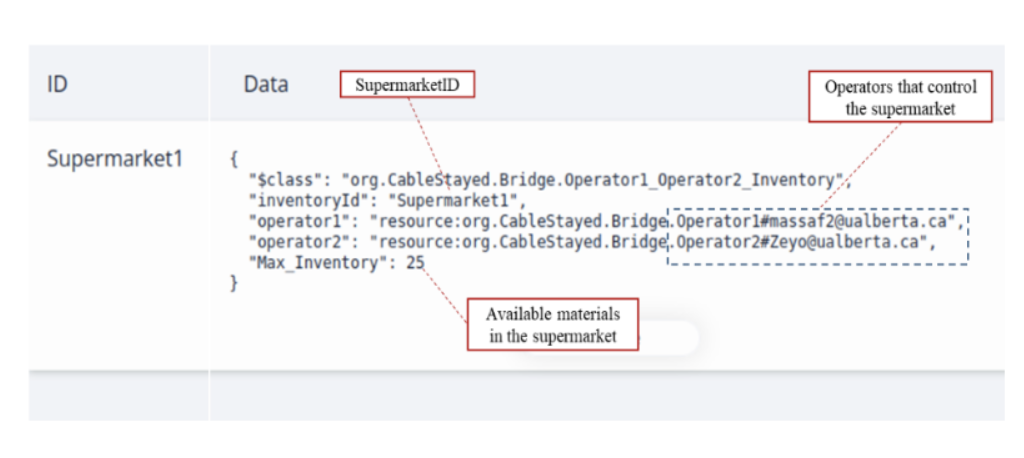

Several scenarios were identified to demonstrate the system's functionality. First, the model is tested when a material (steel girders) is required by Operator 2 (the yard) from Operator 1 (the steel factory). Operator 2 logs into the system using their digital identity. This operator has specific access to the system defined by its access control feature. Operator 2 then selects the transactions section and submits to Operator 1 a Digital Kanban detailing the following: elements' IDs, quantities, and location. Operator 1 then receives a notification on the system regarding the requested items. The smart contract first verifies the request based on an endorsement policy, and then Operator 1 confirms this transaction based on the available data. Table 1 displays the inventory assets after accepting the submitted request from Operator 2, along with the request itself. The available inventory for Operator 1 will decrease by the requested items, while the available inventory for the supermarket between the two stations will increase by the same quantity. In a scenario where the steel factory lacks sufficient steel girders to fulfill Operator 2's request, the system will notify the operator about the material unavailability. Eligible participants can view any submitted requests at any time to monitor the available inventory.

| Step | Details |

|---|---|

| The submitted request by Operator One |

|

| The supermarket update after accepting the request |

|

Besides digital kanbans, the system provides operators with a Pulling Andon feature. In a scenario where an operator discovers a quality issue in one or more elements, they can submit an Andon on the system. The Andon specifies the following data: the element ID, the name of the station, a description of the issue, the Andon pulling time, and the degree of the quality issue (red or yellow). The transaction is visible to all system operators. If the issue is not resolved, the operator then submits another Andon with a red deficiency degree, and all operators in the system will stop work.

The authors created a short demonstrative video of the discussed features of the BIM/smart contract system to showcase how the lean practices are implemented. This video can be found at this link.

Thanks to BIM and smart contract technologies, we believe that lean practices can be put into action, facilitating better productivity, reduced waste, and higher quality.

Mohamed Assaf

Mohamed Assaf Xinming Li

Xinming Li