Contact Information

info@leanconstructionblog.com

Ten Misconceptions in Traditional Construction Changed by Lean

I have always been interested in Psychology -- the study of the human mind. Early in my career I learned this important truism: Success and failure in life are the result of the solutions we choose to deploy. Life's challenges come at us in a constant stream and cannot be avoided.

Why Good Coaching is the Missing Link in Your Lean Journey

You've invested in Last Planner System training. Your team understands target value design. Everyone knows the theory behind - insert XYZ Lean thinking/tool/process. So why do people keep reverting to old habits when challenges arise?

Why Modern Construction Demands Both CPM and Lean: The Future Is Hybrid

For decades, the Critical Path Method (CPM) has served as the backbone of construction scheduling. It's detailed, deterministic, and provides the long-range visibility executives need to forecast outcomes, manage risk, and protect margins.

Should Capital Project Owners Specify Project Performance Standards?

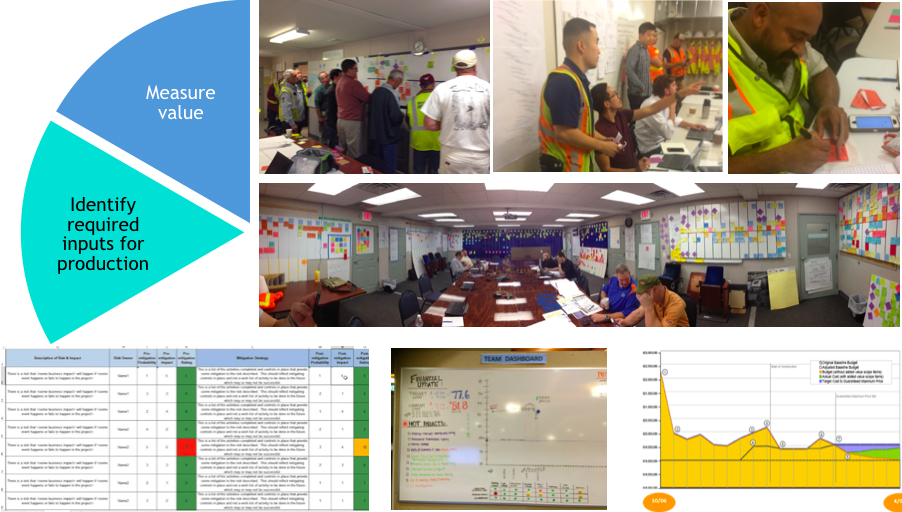

The cost of relinquishing this responsibility is 10% to 20% in additional construction costs and an additional 20% to 30% of time to complete the project. This additional project burden is due to the nature of multidisciplinary, multi-contractual work.

Is Your Team Lean-Healthy? A Framework to Measure What Really Matters

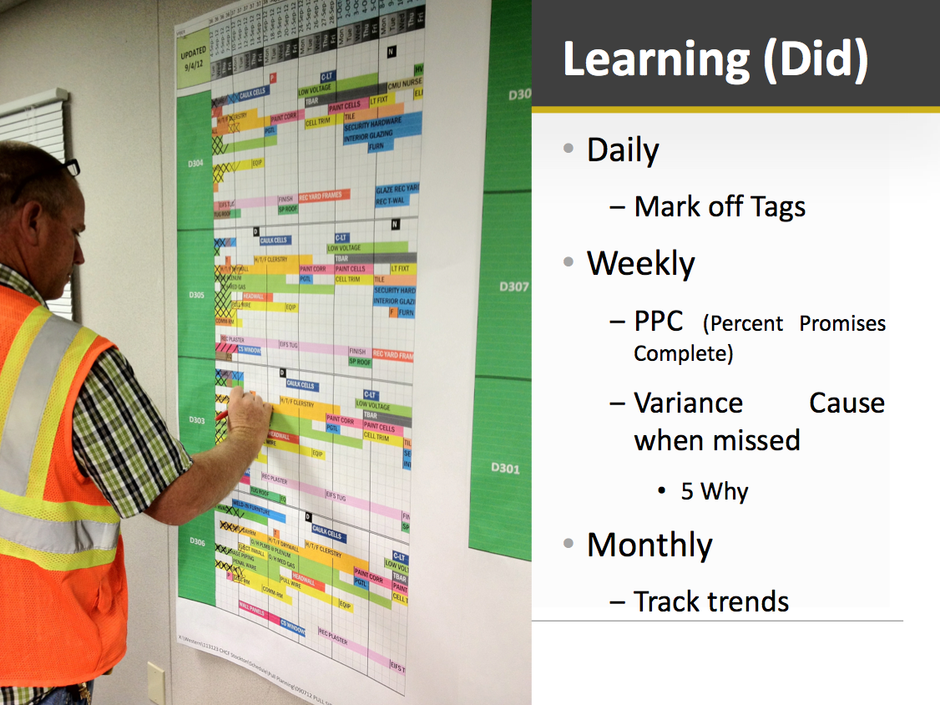

In lean construction, we often focus on tools—Last Planner, Takt planning, and pull planning. But what if the real key to success isn't just the tools, but the people and culture behind them?

Industrialized Construction in Colombia: Challenges and Opportunities Through a Lean Lens

Industrialized construction (IC) is often presented as a pathway to higher productivity, cost efficiency, and better quality. Standardization, prefabrication, and stronger supply chains are central to this vision.

Beyond Meeting Rooms: The Hidden Dynamics of Interdisciplinary Design Collaboration

Effective collaboration in interdisciplinary design meetings is critical for successful project delivery. Yet, despite the presence of all key stakeholders around the same table, collaboration often falters.

How to Create Efficient and Effective Supply Chains

COVID 19, the war in Ukraine, industrial action at ports and several other factors, are causing supply chain challenges across all industries including engineering and construction. Additionally, project supply chains are known to be inherently complex and dynamic.

Building an internal lean infrastructure to scale up lean deployment in a company with over 10,000 employees

WasteWalk Observations have led to the identification of over $300MM worth of estimated and $52MM of actual net cost savings/added value on over 300 projects and yards. 2024 saw the highest employee engagement in WasteWalks since introducing them as a Building Smarter best practice in 2022.

Last Planner and Takt Software Directory

This directory contains all of the Last Planner and Takt Software on the market. We encourage you to do your own research, set up a call with the vendors, and choose the software that fits your needs. This directory is meant to make it easy to find, compare, and make the decision on which software you can use.

Ines Verdun

Ines Verdun

Müge Tetik

Müge Tetik

Laura Avery

Laura Avery

.png)

_+-+Part+1+of+3.png)